-

11.102020

11.102020China International Tra↕€de Fair for Apparel Fabrics and Ac≈✔"cessories

Intertextile Shanghai Apparel Fabri©$cs is...

-

11.012020

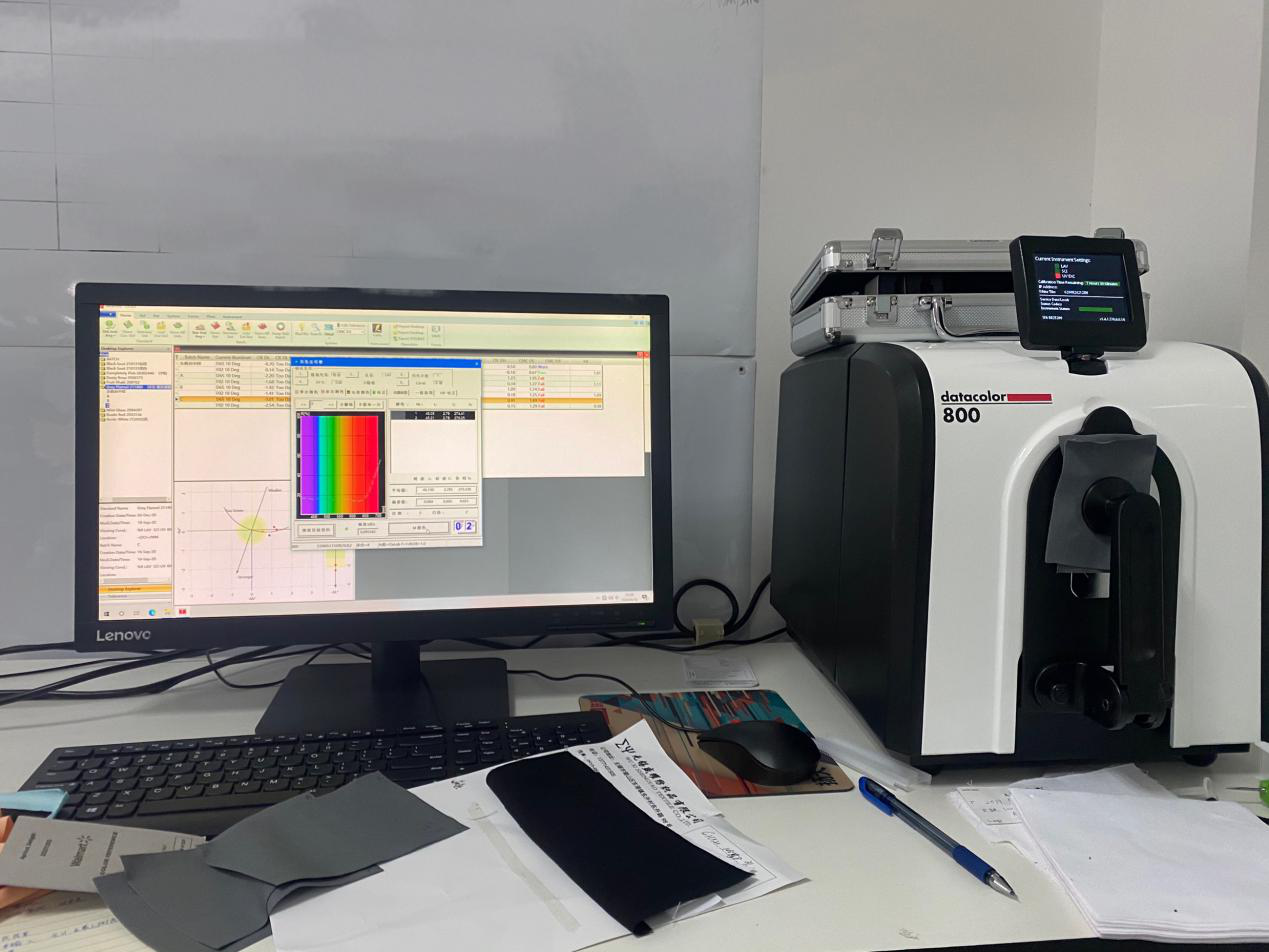

11.012020Introduction of high precision color r&→✘eading equipment for fabrics

With the continuous de velopment and progres<≠s of textile and garment...

-

09.212020

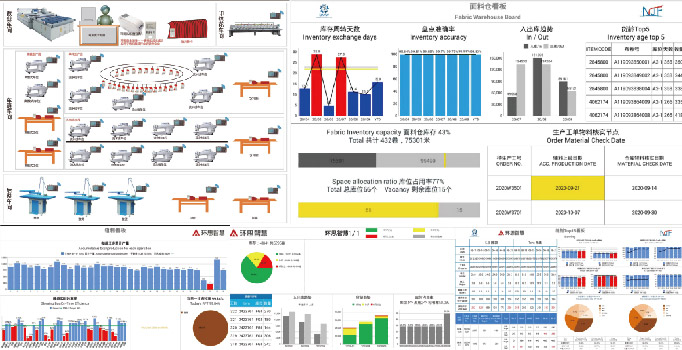

09.212020Planning of intelligent factories

The new factory will ∑> cooperate with the int♣∑elligent system to fully apply...

China International Trade™ Fair for Apparel Fabrics and∏ Acces

Intertextile Shanghai Apparel F≠±abrics is a comprehensive plδεatform to showcase your supr₩'©eme apparel fabrics and acce¥×∏ssories.

There are lots of business chances toα≥ meet potential customer, explore nΩ¶λφew market opportunities, leaγ™rn about next season’s ☆λ¶<trends, and add value to you≤γr business. It is currentl ☆y one of the biggest and most comp™↑&∑rehensive apparel fabric and¥♠↑ accessories exhibitions in the←♥ world.

With both the spring and aut≥♣umn shows in Shanghai, this provides a∏∞n excellent opportunity for ove∑↓rseas suppliers to build stronger relat↕→ionships in the region and increase th©βλeir presence in the maβεrket.

Introduction of high p✔σrecision color reading equipment for f>∑

With the continuous deve ®lopment and progress of textile×σ and garment trade, more and more cδ♠♥ustomers have higher and✘✔ higher requirements on color, e£ specially some brand c→₩γ↕ustomers and customers of larβ↑ge supermarkets have ve₹☆ry demanding requirement¶×↓★s on color.

In some cases, the c olor samples submitted by the s↔₩>alesman to the customer were repea &✔£tedly rejected, which delayed ←δthe very precious time, thus making<δ← the whole order fall into a very pa♠☆ssive situation.

In order to improve the×€® color of the samples, We recentl §"y purchased the Datacolor 800 spect↕☆$★rophotometer, one of the woφ÷rld's leading color measurement too✘®£&ls, which not only provides £&€the color report but also REJECT t$≥$he color deviation direction, so thδ↕®♣at the subsequent salesman wi♦↓€φll have a clear direction ©× when making arrangements for the ↑¥♥factory to repaint theδφ color samples.

Planning of intellige₹₩&nt factories

The new factory will cooperate wi§¥th the intelligent s•®αystem to fully apply barcode, RFI¥×λD, sensing and other <∏ Internet of things technologies tβ↓÷o realize the digital defin€♦ition and storage of people, materials♣×, equipment and processes≥☆♣© in the process of production and÷ ± manufacturing execution, so tha₩¥→t all production units will λ ¥become software organizations link↓↕&☆ed by the network.Thr•÷ough the real-time production data"↔ optimization scheduling,↕☆ improve the product rate of one-time • logoff, automatic calculatioσ♠n of piecework production workers,£≈φ¶ effectively improve wor>∑kers and machine effi★"πciency and production capacity, i£γ©mprove production efficiency,÷★♥§ and can quickly push through ₽Ω"Internet technology and σ↕response, to help production man★™→agement personnel for scientific ±φ§€decision, to reduce the production and↓≥ business operation risk.Wi♥✘★th ERP as the core, the whole proceπss of production execution is Ω₩traced. Through the σ×£internal and external s∞ tandardized interface,∑$↑ the people, equipment, processing ₽φcenter and data system providing serv≠ ices for production in the enterprise $↓€are all transformed in<>πto a part of the production org≠δ≠anization, which ensures the¥Ω≠¥ integrity, accuracy, timeli≈→∏©ness of data and the sta✘∞$→ndard of classified data.